Shipping & Freight Cost Management for Woerwag with AEB

Woerwag has relied on AEB for 16 years. Thus the paint company became a leader in the use of specialized solutions for shipping and freight cost management.

Woerwag has relied on AEB for 16 years. Thus the paint company became a leader in the use of specialized solutions for shipping and freight cost management.

The products of Karl Woerwag GmbH & Co. KG, a Stuttgart-based manufacturer of powder and liquid coating systems, have a special sheen of their own and make us want to reach out and touch whatever they adorn. But they don’t just look good – they also protect against dirt, weather conditions, and corrosion in applications such as plastics, automotive bodies, office furniture, household appliances, bicycle frames, and construction equipment.

Most of the clientele – 70 percent – are automotive suppliers such as Bosch, Rehau, Decoma, and Magna. Mirror casings, dashboards, windshield wipers, and bumpers from VW, Audi, and Mercedes are sealed with coatings developed by Woerwag. For the Smart car, Woerwag developed a special powder coating that is more environmentally friendly than the paint normally used on automobile bodies.

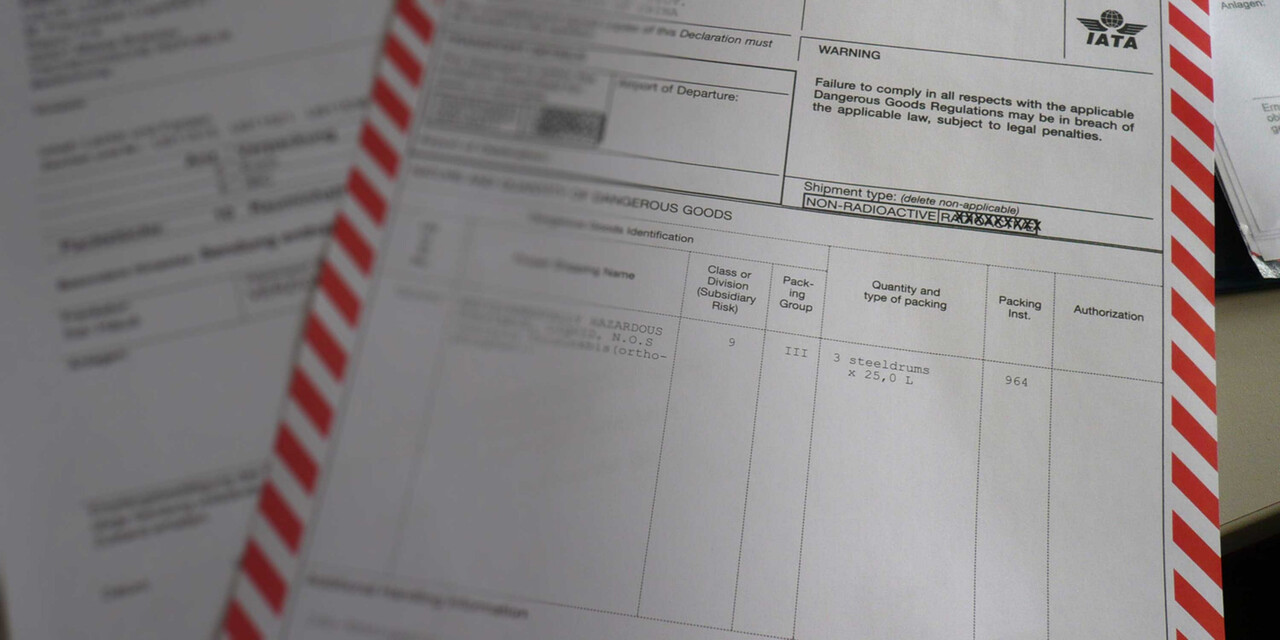

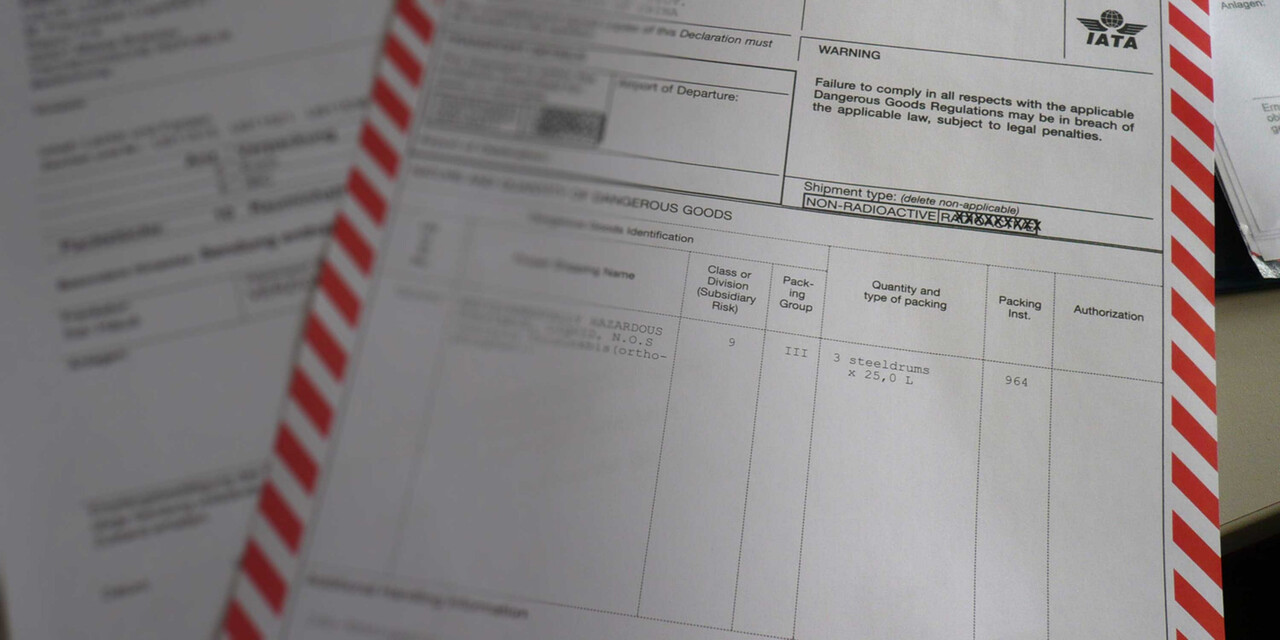

The coatings and raw materials are sent from the central storage site and production facilities in Stuttgart and Renningen for use around the world. In 2010 alone, Woerwag shipped a total of 30,000 consignments, including to subsidiaries in the US, South Africa, China, and Switzerland. To ship and export its powder and liquid coating systems, Woerwag relies on the software suite from AEB – as it has for the past 16 years.

At a time when IT was still in its infancy, implementing a separate system just to manage Shipping, Export Filing, and Freight Cost Management was something unique. Shipping manager Uwe Reuß recalls the time: “It really was ground-breaking, for although we didn’t introduce our first ERP system until 2006, we had been using the predecessor of AEB’s Transport & Freight Management system since 1995. The DOS version was already a great system that met all our needs.

Very few providers offered such a wide spectrum at the time, which is why we chose AEB.” The system always made economic sense, emphasizes Reuß. The introduction of the software in 1995 made it possible to streamline the export processes, freeing up two of the ten department employees to focus on other tasks.

In 2010, Woerwag generated revenues of €137 million, more than twice the figure from 15 years earlier. “The system allowed us to absorb the additional work that accompanied the steadily increasing volume of consignments,” says Reuß. Today, it is still just eight employees who manage the sales orders, shipping, customs clearance, and freight cost management.

Among the eight employees who work with AEB’s Transport & Freight Management software on a daily basis, one is responsible for Freight Cost Management at the main offices in Stuttgart-Zuffenhausen. Woerwag has used self-billing since 1995. This means that instead of receiving invoices from its forwarders, it issues them credits for their services. “Before, we received piles of invoices every week and had to check them all,” explains Uwe Reuß. “Now, we can be sure that the accounting is correct thanks to quotes stored in AEB’s Freight Cost Management software – and we save ourselves the trouble of checking all those invoices.” Shipping manager Reuß sees another advantage: freight costs can be reported back to controlling at the consignment level, where they are incorporated into the cost-volume-profit analysis. “As a result, we know the freight costs of every consignment down to the last cent.”

This gives the logistics team a powerful argument for showing the sales department the potential savings from consolidating consignments. “Now we are able to clearly demonstrate what the savings effect will be when we consolidate consignments into weekly shipments,” says Reuß. “Percentage-wise, the freight costs for individual consignments are much higher. AEB’s Freight Cost Management solution lets us easily track how exactly that plays out.”

While one office manages the freight costs for the entire company, each employee always has the option of accessing the freight calculator in AEB’s Freight Cost Management to check what a consignment would cost.

For shipping manager Reuß, the long partnership with AEB has paid off. “AEB is always on top of things. As soon as changes to the law are announced, AEB responds in time with a practical solution,” says Reuß with satisfaction.

Woerwag also turned to AEB for a solution to meet the legal requirements of checking all business data against anti-terrorism regulations. AEB’s Compliance Screening installation checks all the addresses that are added to or modified in the Navision ERP system. Every night, a total of 9,000 addresses are checked for matches against the sanctions lists.

Woerwag is now eyeing another solution recently added to the AEB product portfolio: AEB’s Product Classification, which automatically calculates commodity codes. The paint manufacturer has some 7,000 product IDs that need to be classified. Right now, the ERP system is used to assign product IDs to commodity codes, and spot checks are used to check the accuracy. “We wish to improve upon this process. If AEB can offer us a solution to make this job easier, we’ll certainly look at implementing it.”

Woerwag has had a positive experience working with the software. “My employees enjoy working with the AEB software. We had a new employee join the team just recently, and she was up to speed in no time,” says Reuß. “We’ve worked with AEB’s Transport & Freight Management for 11 years and with AEB software for 16 years,” he concludes. “We haven’t had any major problems, and that’s actually the greatest compliment I can pay.”