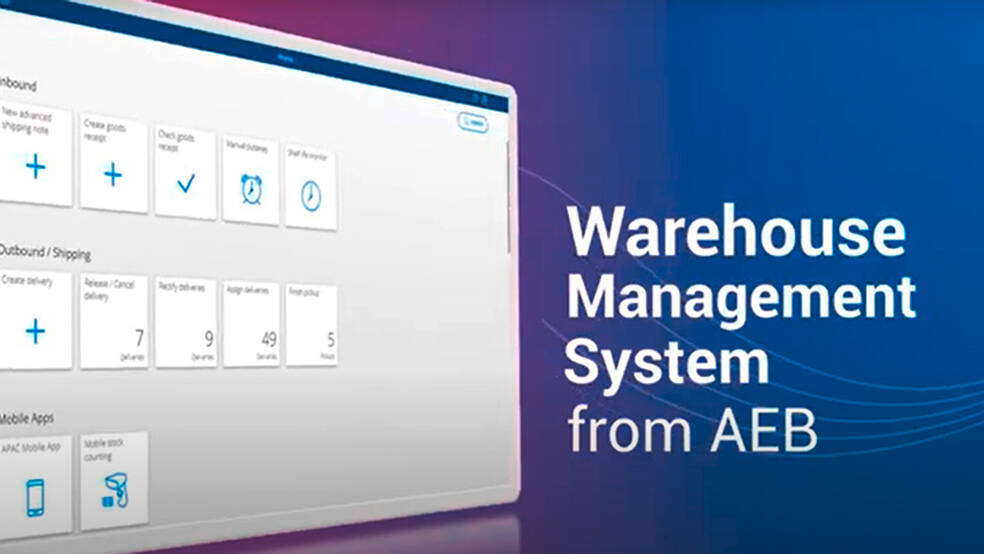

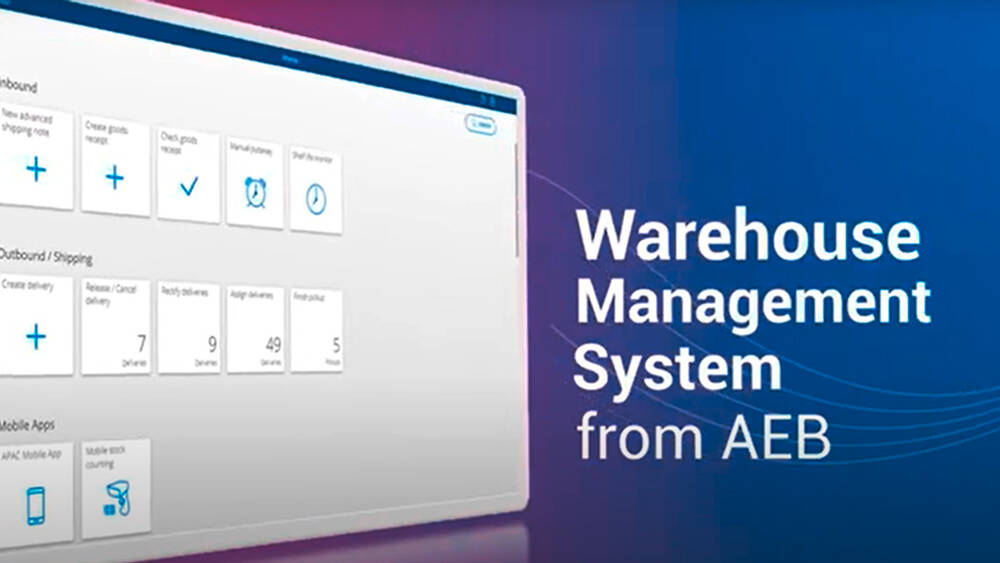

AEB warehouse management software: take your processes to the next level

With our warehouse management software, we realize a smart approach to digitization, using the most efficient warehouse technologies and concepts for your individual warehouse. For quick implementation and a fast return on invest.

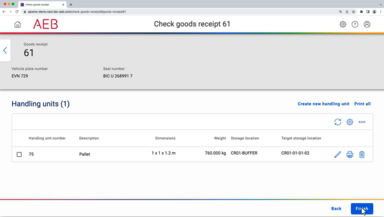

100% transparency & traceability

Identify inventory bottlenecks and get real-time traceability for every article, box and batch.

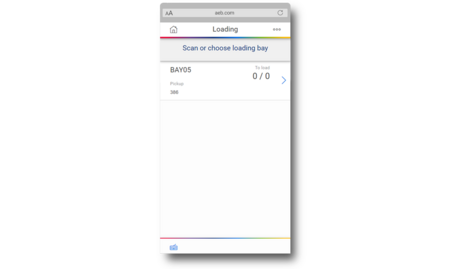

User interface fits perfectly to any device

Our WMS runs optimally on mobile devices and other laptops, terminals and touchscreens.

Smart, efficient picking processes

Use smart glasses, mobile scanners and pick-by-voice to increase efficiency.

Optimal automation, low costs

Easily integrate components such as automated guided vehicles or AutoStore®.

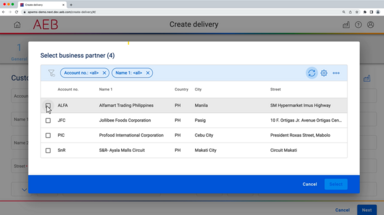

Smart packing & shipping processes

AEB warehouse management software also supports your shipping processes. With smart automation and integration of your carriers, you reduce lead times and increase delivery quality.

- Implement multi-level and qualified packing

- Create smart consignments, consolidate delivery notes into one consignment

- Print shipping notifications and documents

- Connect with 250+ carriers out of the box

- Print shipping labels and generate EDI messages and loading lists

AEB software for comprehensive supply chain excellence

Warehouse operations are only one part of a comprehensive logistics excellence required for full customer satisfaction and efficiency. AEB software helps you with many other tasks in the supply chain and provides end-to-end process support.

Transport management

All transports. Inbound and outbound. Execution and control in one platform.

Customs management

Integrate import and export direct filing and your customs brokers into your processes.

Worldwide export controls

Export control, sanctions list screening, end-use and provisioning prohibition screening.

Warehouse management software from one source: planning, implemenation, optimization

A warehouse management system from AEB doesn’t start with the software – and it doesn’t end there, either. We work alongside you until your solution and processes are up and running smoothly. And our professional support team helps you after go-live with your questions and tasks.

Among others, AEB services around warehouse management software include:

- consulting & process design

- planning & implementation

- hardware selection

- ramp-up and on-site support

- customer support and success management

The AEB partner network: The best and brightest for your success

Smart automation and efficient processes don’t just require a customized WMS, they also need the right hardware. We’ll help you select the right equipment for your warehouse, tap into our partner network to get it delivered, and help you configure your:

Handhelds, forklift terminals, scanners

consulting & planning services

pick-by-voice, pick-by-vision

Material flow computers

Storage and racking technology

Handhelds and barcode scanners

AEB software trusted by 7,000+ customers – hear two of them:

Talk to an AEB warehouse management software expert – get a free demo

Learn how AEB warehouse management software helps other companies achieving logistics excellence. And learn how it can help you.

Frans Kok

General Director

Paul Rivera

Category Manager WMS

Aiza Esteban

Senior Business Development Manager

Daisy Pacheco

Solutions Consultant